Industry Trends: Innovation and Development of Packaging Materials

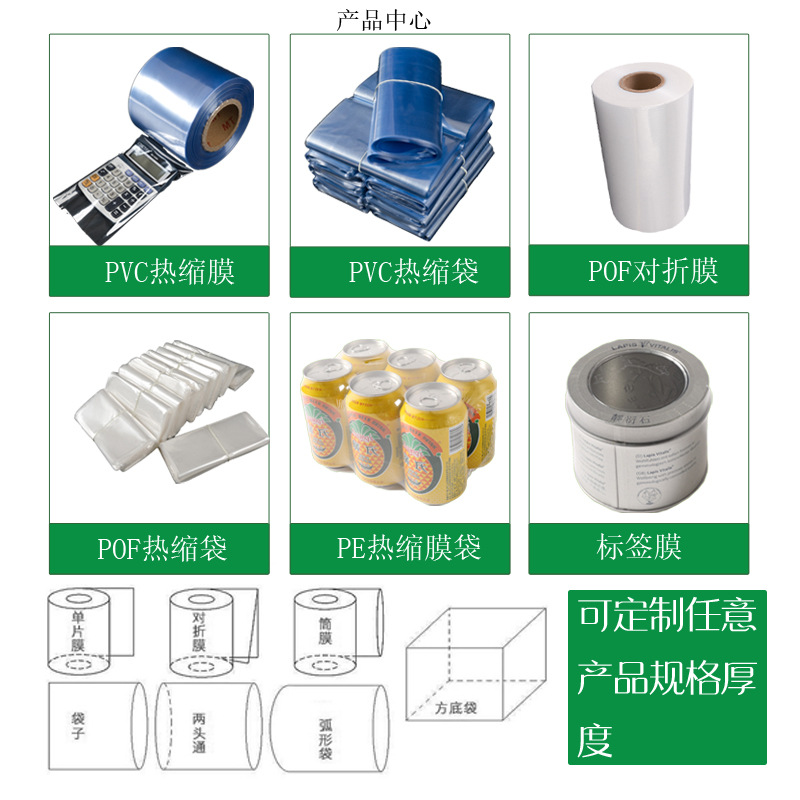

With the advancement of technology and changes in consumer demand, packaging materials are constantly innovating and developing. Especially in the food, beverage, electronics and other industries, efficient packaging solutions become particularly important. As an advanced packaging material, heat shrinkable film has gradually become the first choice in the market because of its excellent performance and wide range of applications. This paper will deeply discuss the characteristics and applications of POF, PVC and PE three kinds of heat shrinkable film.

POF Heat Shrink Film: The Packaging Choice for High Performance

POF(Polyolefin) heat shrinkable film is a high-performance heat shrinkable film made of polyolefin material. It has high transparency, good gloss, good toughness and other characteristics, suitable for a variety of complex shapes of product packaging. POF heat shrinkable film is not easy to crack during the shrinkage process, which can well protect the product from the external environment. In addition, its low shrinkage temperature makes it suitable for temperature-sensitive products.

PVC heat shrinkable film: economical and practical multi-purpose option

PVC (polyvinyl chloride) heat shrinkable film is a relatively low-cost but stable heat shrinkable film. It has good transparency and mechanical strength, and is suitable for packaging in food, beverage, daily necessities and other industries. PVC heat shrinkable film has a higher shrinkage temperature and can achieve a higher shrinkage rate, which is suitable for products that need to be tightly wrapped. However, due to its poor environmental performance, some countries and regions have certain restrictions on its use.

PE heat shrinkable film: environmentally friendly and durable packaging solution

PE (polyethylene) heat shrinkable film is an environmentally friendly heat shrinkable film with good toughness and tear resistance. It is suitable for packaging in food, medicine, cosmetics and other industries, especially for products that need long-term preservation. The shrinkage temperature of PE heat shrinkable film is moderate, can be used in a wide temperature range, and has good adaptability. In addition, it also has good moisture resistance and can effectively prevent moisture penetration.

Material Comparison: POF vs PVC vs PE

Choosing the right heat shrinkable film material is essential to ensure packaging quality and efficiency. POF heat shrinkable film is favored for its high performance and wide applicability, but the cost is relatively high. Although PVC heat shrinkable film is cheap, it has certain limitations in environmental protection. PE heat shrinkable film is known for its environmental protection and durability, and is suitable for industries with high environmental protection requirements. Companies should consider factors such as cost, performance and environmental protection when choosing.

Application Scenarios: From Food to Electronics

Heat shrinkable films are widely used in various industries. In the food industry, it can be used for the packaging of bottled water, fruit juice, canned food and other products to ensure food safety and hygiene. In the beverage industry, heat shrinkable film can realize multi-bottled combined packaging and improve transportation efficiency. In the electronics industry, it can be used for the packaging of precision products such as mobile phones and computer accessories to prevent static electricity and physical damage. In addition, heat shrinkable film is also widely used in daily necessities, medicine, cosmetics and other fields.

Production process: a key step to ensure quality

High-quality heat shrinkable film cannot be separated from strict production control. From raw material selection to finished product inspection, every link needs fine management. The first is the choice of raw materials, must use high quality resin particles, to ensure the basic performance of the film. The second is extrusion molding, which forms a uniform film through precise temperature and pressure control. This is followed by cooling and shaping to ensure the dimensional stability of the film. Finally, quality inspection, including thickness, transparency, shrinkage and other indicators to ensure that the product meets the standard.

Packaging Equipment: Efficient Automation Solutions

Efficient packaging equipment is a necessary condition for mass production. Modern heat shrinkable film packaging lines usually adopt a fully automatic control system, from feeding, bag making, sealing to shrinking, each step is automatically completed by the machine. This not only improves the production efficiency, but also reduces the error caused by human operation. At the same time, the advanced temperature control system and cooling device ensure the uniformity and stability of the film material during the shrinkage process.

Customer Stories: Success Stories and Experience Sharing

Many companies have significantly improved packaging quality and efficiency by using our heat shrinkable film products. For example, a well-known beverage company uses POF heat shrink film for multi-bottle packaging, which not only reduces logistics costs, but also enhances brand image. Another electronics manufacturer chose PE heat shrinkable film to effectively protect precision parts and reduce repair rates. These successful cases prove the reliability and advantages of our products.

Selection Guide: How to Choose the Best Heat Shrinkable Film

Choosing the right heat shrinkable film requires consideration of multiple factors. First, identify your product type and packaging needs and determine the required film properties. Second, evaluate the budget and cost and choose the most cost-effective product. Third, examine the strength and technical support capabilities of suppliers to ensure product quality and service levels. Finally, the sample test is carried out to verify whether the actual performance of the film meets the expectations.