Innovative Technology: The Evolution of Heat Shrinkable Film Materials

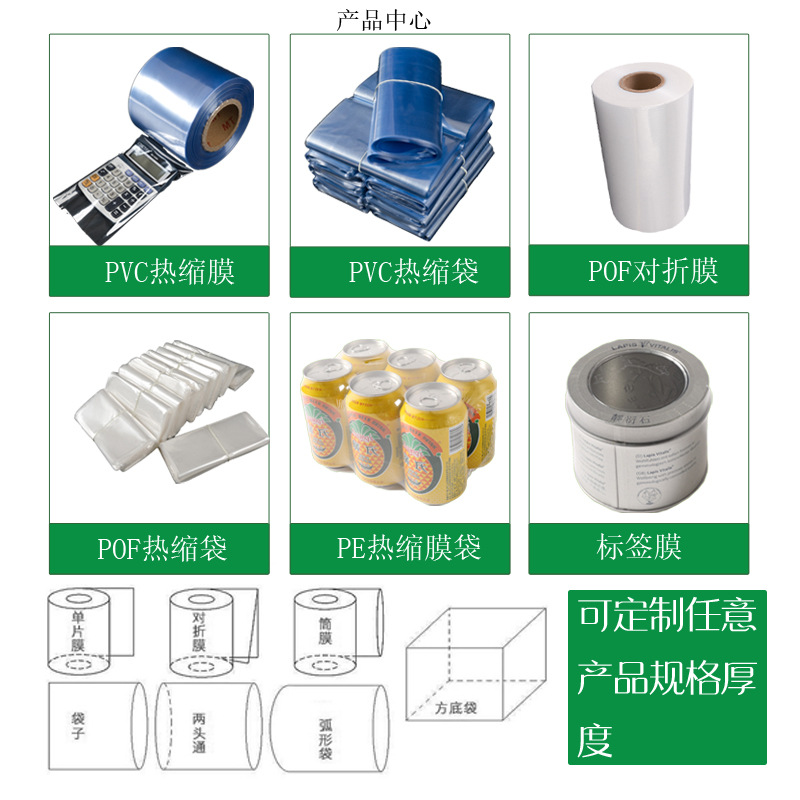

From the early days of simple plastic films to today's highly specialized and diverse heat shrinkable films, the development of this technology is impressive. In particular, it is worth mentioning that the three materials currently used in the market-polyolefin (POF), vinyl chloride copolymer (PVC) and low-density polyethylene (PE)-have undergone many innovations and upgrades. These new materials not only have excellent physical properties such as high strength and good flexibility, but also have made important breakthroughs in environmental protection.

Take the latest fifth-generation POF as an example, it can complete an efficient heat shrinkage process at a lower temperature and will not release harmful substances to pollute the environment. In contrast, although traditional PVC is cheap, it has many limitations and is now moving towards reducing the amount of plasticizer. As for PE materials, they are favored for their natural good air permeability and easy degradation characteristics. As consumers' recognition of the concept of sustainable development continues to increase, we will see more new generation of heat shrinkable films with high performance and eco-friendly characteristics come out in the future.