Reveal three hot heat shrinkable film materials

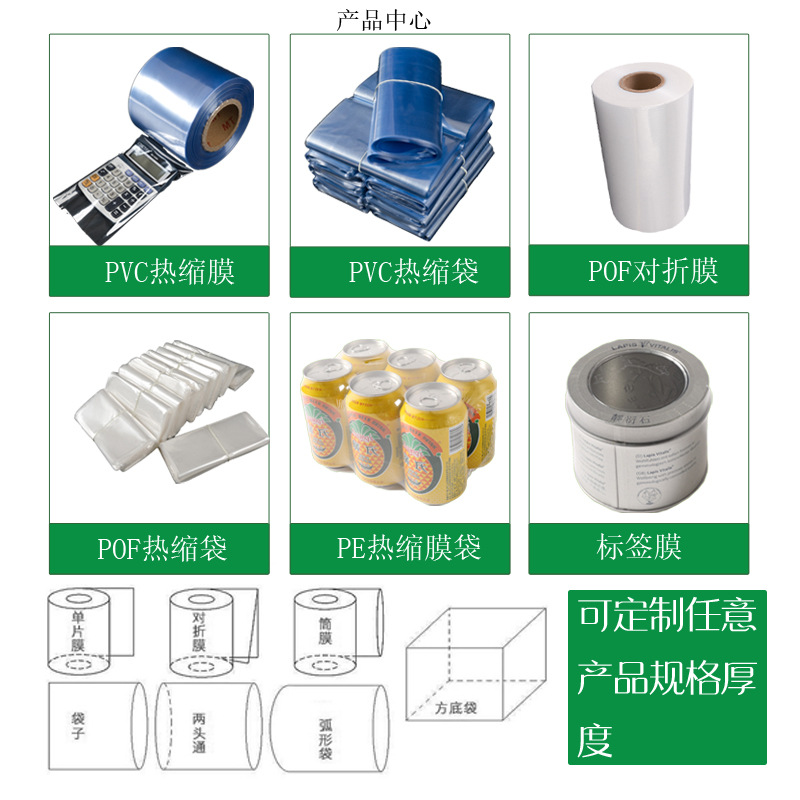

Among the many types of heat shrinkable films, polyolefin film (POF), polyvinyl chloride film (PVC) and polyethylene film (PE) are favored for their excellent performance. Each material has unique physical and chemical properties, showing their own strengths in different industrial fields. For example, POF has high transparency and good toughness, which is very suitable for food packaging; PVC is known for its durability and is widely used in building material protection; PE is one of the most common choices on the market due to its low cost and easy processing characteristics.

Through an in-depth analysis of these three materials, we will reveal their respective application scope and development prospects, and help readers better understand which material is more suitable as their preferred business development partner. Whether you're looking for high-end customization or an affordable option, there's one here to meet your needs.

From Lab to Production Line: Manufacturing Process Analysis

High-quality heat shrinkable film is inseparable from advanced production technology and technical support. A complete production process involves multiple links, including raw material procurement, pretreatment, extrusion molding, and later quality inspection steps. In this article, we will detail the key elements of each stage and explore how technological innovation can be used to improve product quality and reduce costs.

In addition, we will share some best practices of successful companies and demonstrate their efforts in equipment selection and process optimization, aiming to provide more valuable reference information for our peers. Through continuous improvement and improvement, to ensure that each roll of the factory products are up to the highest standards.

Addressing complex needs: Customized solutions

In the face of growing and diversified market demand, products with a single standard specification can no longer fully meet customer requirements. In order to provide more flexible service models, many manufacturers have introduced tailor-made heat shrinkable film solutions. These solutions can not only accurately match the size and shape characteristics of specific products, but also adjust the thickness, color and even additional functions according to customer needs.

In this section, we will introduce several typical examples of customized products, such as security labels with anti-counterfeiting labels, food preservation bags that can be used for microwave heating, etc., through specific cases to allow users to intuitively feel the convenience of personalized design. This flexibility allows companies to stand out in a highly competitive market environment.

Beyond Traditional Boundaries: An Outlook for Emerging Application Scenarios

With the progress of science and technology and the development of society, the application field of heat shrinkable film is expanding. In addition to the traditional retail industry, logistics and transportation, it has found new development space in environmental protection, energy conservation, health care and other industries. For example, biodegradable heat shrinkable sleeves made of new composite materials help reduce environmental pollution; certain medical-grade sterile packaging materials can ensure the safe storage and transportation of medical devices.

This article will focus on some of the most promising new directions, predict the changes that may occur in the next few years, and encourage companies to actively explore cross-border integration opportunities to jointly promote the innovation and development of the entire industry. No matter in which industry, heat shrinkable film will play an increasingly important role.

User Story Collection: Real Feedback Witness Quality Commitment

Real user experience is often an important measure of a company's strength. To this end, we have specially collected and sorted out some comments from customers from all walks of life, from which we can see the achievements and gains made by different enterprises in the selection of our heat shrinkable film. Some have improved work efficiency and reduced waste; some have improved brand image and won the trust and support of more consumers.

Through the vivid story fragments, you can deeply understand the power behind quality service-not only the attitude of quality excellence, but also the spirit of corporate culture that always adheres to customer demand-oriented. Every user's satisfaction is our greatest affirmation.