Exploring Efficient and Economical Packaging

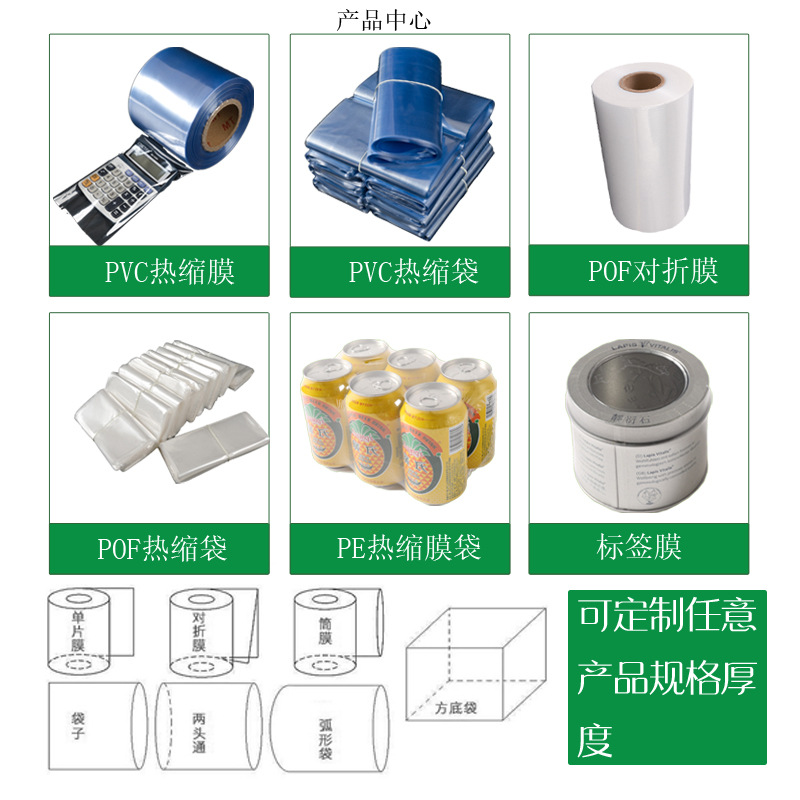

In today's competitive business environment, businesses and merchants are facing increasing challenges related to logistics, transportation and product presentation. In order to deal with these problems, high quality packaging materials have become particularly important. In this regard, our factory provides a variety of types of heat shrinkable film options, designed to meet the unique needs of various industries.

From food to electronics to groceries and other consumer goods, each segment has different packaging requirements. Take POF (polyolefin), PVC (polyvinyl chloride) and flat bags as examples, these materials are widely used in various industries due to their excellent properties. For example, the use of highly transparent and flexible POF film in fresh fruits and vegetables can effectively prevent water loss; and for precision instruments, it is recommend to choose PVC material with high temperature stability to ensure safe and undamaged to reach the destination.

Through specific case studies, it can be seen that the rational use of these high-level heat shrinkable packaging materials can not only significantly reduce the breakage rate and thus save costs, but also improve the speed and flexibility of the entire supply chain operation. A well-known snack manufacturer once faced the problem of damage to goods caused by moisture in traditional carton packaging. Later, after switching to our new PE plastic shrink cap, it not only solved the problem of moisture but also enhanced the visual appeal of the brand and won more market share.

Deep understanding of core material properties

Let us further explore the basic properties of the three mainstream heat shrinkable films and their scope of application:

Polyolefin (POF): Its biggest feature is extremely high transparency and good optical performance, which is very suitable for situations where internal products need to be clearly displayed, such as fresh agricultural products or high-end gift packaging.

In addition, it has excellent softness and tensile strength, and can easily adapt to complex shapes without affecting the quality of the seal.

This is a good choice for brands that want to impress consumers.

Polyvinyl chloride (PVC): PVC is a tough and wear-resistant material, especially suitable for the safe packaging of sensitive objects such as electronic components. It can withstand environmental changes in a wide temperature range without deformation or fracture.

Another important advantage is that it is easy to form and process, so it can be made into various containers and accessories of different sizes according to specific applications.

If you are looking for an ideal solution that is both strong and beautiful and protects valuable assets from external interference, please consider PVC products.

Polyethylene (PE): PE is usually used to make light and practical daily necessities, such as laundry detergent bottle caps or small household appliance shells.

Its advantage is that it has low cost but good mechanical properties, that is, it is not easy to break and can maintain long-term deformation.

Therefore, when the budget is limited and do not want to sacrifice too much quality, PE is definitely a wise move.

In short, choosing the right heat shrinkable film is very important, because it is directly related to the quality of the final product. Whether in the degree of durability or appearance effect has a decisive influence.

Excellent Protection and Beauty

In addition to providing a reliable physical barrier (such as dust, water and impact resistance), excellent heat shrinkable film can also greatly enhance the overall image of the product. Many well-known brands are using this technology to achieve better marketing results.

For example, a well-known cosmetics brand in its new series of products for the first time with exquisite printing pattern of PE shrink sleeve, once listed immediately attracted the attention of a large number of young female consumers. They have said that this kind of packaging not only looks high-end, but more importantly, every time they get it, they will have a special sense of ceremony.

In addition, we are constantly pursuing technological innovation to meet the growing market demand. At present, the company has mastered a number of leading printing processes, from color matching to fine texture portrayal and other aspects to provide customers with personalized customized services. This means that every factory product will become a unique work of art, which will win the favor and support of more loyal users.

Tailored packaging solutions

We know that the specific situation of each company is different, so the actual needs and development plans of customers must be fully considered when formulating packaging strategies. Based on this principle, we will be happy to provide you with comprehensive and thoughtful professional advice and guidance