In the modern packaging industry, heat shrinkable film is widely welcomed for its excellent protection and decoration. However, among the many options, how to choose the product that best suits your needs? This article will take you through the core characteristics of the three main materials PVC, POF and PE and their application scenarios.

Material Selection Guide for Heat Shrinkable Film: Understanding the Core Values of PVC, POF and PE

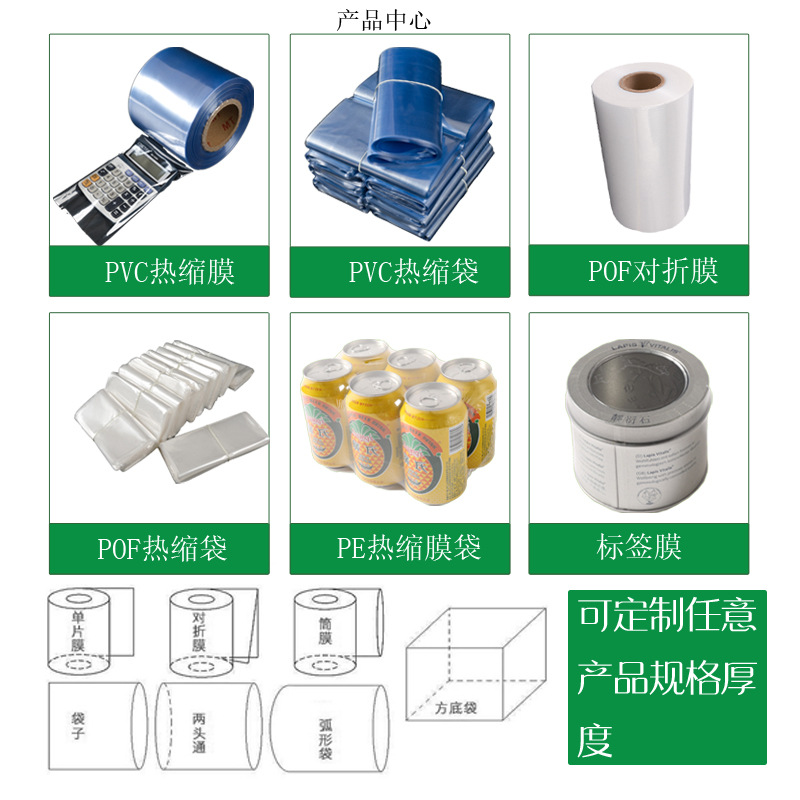

PVC (polyvinyl chloride) has long been a popular choice for its transparency and flexibility, while POF (multi-layer co-extruded polyolefin film) stands out for its excellent tear strength, and PE (polyethylene) is also favored for its economical and easy processing characteristics.

Industry insight: performance analysis of different materials in various packaging scenarios

Different product types need to match the corresponding heat shrinkable film to achieve the best results. For example, the food and beverage field is more inclined to choose safe and environmentally friendly and sealing PE materials, electronic products, preference for high temperature resistance and high surface gloss PVC products, and for daily chemical products, taking into account the soft touch and high toughness of POF is undoubtedly one of the best solutions.

Balancing environmental protection and performance: why more and more companies prefer specific heat shrinkable films

As consumers are increasingly concerned about sustainable development, companies are also beginning to focus on green attributes when selecting packaging materials. Among them, PE, which can be recycled or degraded quickly, has gradually become the new darling of the market. At the same time, manufacturers are constantly improving the process to reduce energy consumption.

Cost-Benefit Analysis: How to Achieve Budget Optimum with Smart Material Selection

In addition to considering functionality, the price factor is also an important link that cannot be ignored. Although the high-end customized POF has a large initial investment, it has a long service life and a short return period. Ordinary versions such as PP/PET composite structures are relatively cheap but can also meet basic needs. It is therefore important to weigh the pros and cons according to specific project requirements.

Future Trend Outlook: Potential Impact of Heat Sealing Film Technology Innovation on Enterprises

the progress of science and technology is promoting the transformation and development of the whole industry. The new nano-coating technology enables traditional plastics to have stronger antibacterial ability. After the intelligent sensing chip is embedded, each independent package can have a unique identification, thus facilitating tracking and management, etc. are all directions worth looking forward.

To sum up, a reasonable selection of suitable heat shrinkable film can not only ensure product quality but also save operating expenses, and follow the trend of the times towards a more bright and brilliant development path!