With the increasingly fierce market competition, the demand for efficient and attractive packaging is increasing. As a modern technical means, heat shrinkable packaging is being favored by more and more enterprises because of its excellent protection and aesthetics.

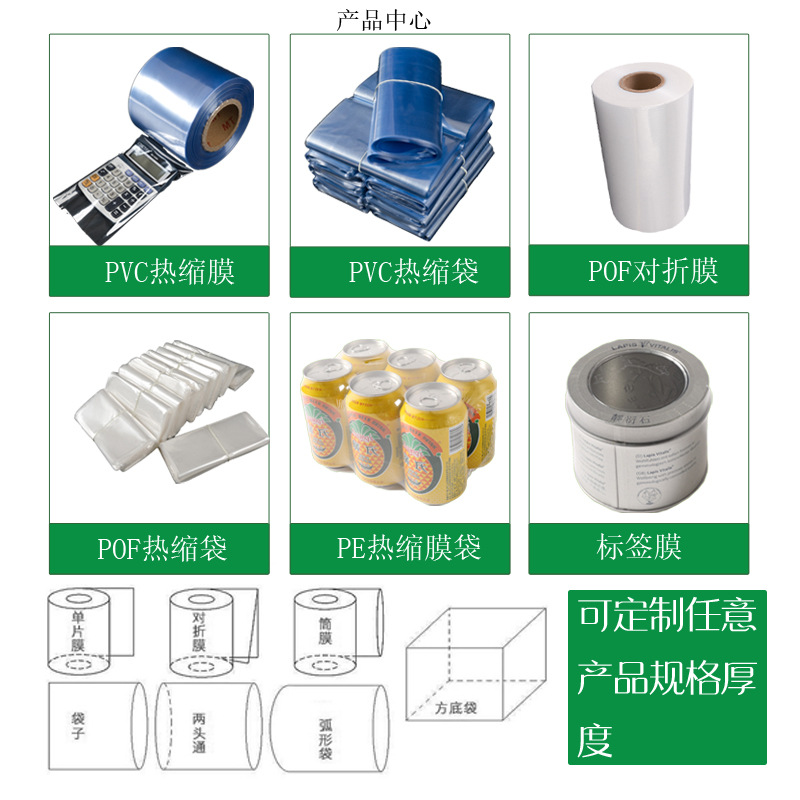

However, in many types of heat shrinkable film, how to choose the right products for their own business has become a major problem for many business managers. Next, we will give you a detailed analysis of the three mainstream heat shrinkable films-POF (polyolefin), PVC (polyvinyl chloride) and PE (polyethylene), and discuss their respective advantages and application areas.

Core differences and analysis of strengths and weaknesses:

First of all, let's look at POF heat-shrinkable film, which is a material with high flexibility and good transparency. It is widely used in the food and beverage industry and the outer packaging of electronic products. It has excellent tear strength and is easy to process, but the relatively high cost may be a factor for some small businesses.

PVC film is known for its moderate hardness and high recycling rate. Although there is a certain risk of environmental pollution in the production process, it is still an economical choice under appropriate conditions, especially suitable for packaging toys or stationery products.

In contrast, PE material pays more attention to durability, such as agricultural mulching film and other fields have outstanding contributions. However, due to the large thickness, the gloss is insufficient, which limits the application possibility of some high-end markets.

Actual case sharing:

Take a well-known snack manufacturer as an example. After many tests, they decided to use POF heat-shrinkable film to wrap the new series of candy bars on the market. This not only ensures that there is no damage during transportation, but also improves work efficiency through machine automation.

For a local handicraft workshop, considering the limited budget and small order volume, they chose a more cost-effective PVC solution to complete the work display box reinforcement work.

Selection Guide:

It is essential to develop a reasonable procurement plan for the specific conditions of different user groups.

if it is the first time to try this technology, it is recommended to start from small-scale experiments to accumulate experience and then gradually expand the scope of investment; for those large enterprises that already have a mature supply chain system, they can obtain greater discounts through mass customization to reduce the proportion of costs and expenditures.

Environmental Protection and Safety:

Nowadays, the concept of green and sustainable development is deeply rooted in the hearts of the people all over the world, so any link involving the production of plastic products must pay attention to environmental protection issues. For example, measures such as minimizing the waste of raw materials and achieving the goal of resource recycling through technological innovation are worth learning and adopting.

Future Trend Outlook:

In recent years, biodegradable heat-shrinkable films have gradually emerged, and are expected to replace traditional chemical synthesis raw materials to occupy a dominant position in the next few years. At the same time, the introduction of intelligent equipment will further simplify the operation process to improve the level of precision control for enterprises to bring more convenient conditions.

In short, no matter what type of heat shrinkable film has its unique charm. The key is to make wise decisions based on the actual situation. Only in this way can we achieve twice the result with half the effort in a real sense!